STEEL

Being the representative for Damasteel ™ This page is dedicated to the steels that they offer and which I have for sale. Please note that I do not carry all the damascus steel types in stock. This is not really an issue as the build time from the factory for standard sizes is not normally more than 2 weeks.

Special requests: Damasteel™ will gladly make up special requests in steel for you. there may however be a minimum length or order depending on the steel you require. Please contact me so we can help you?

Please will you contact me through he contacts page for prices.

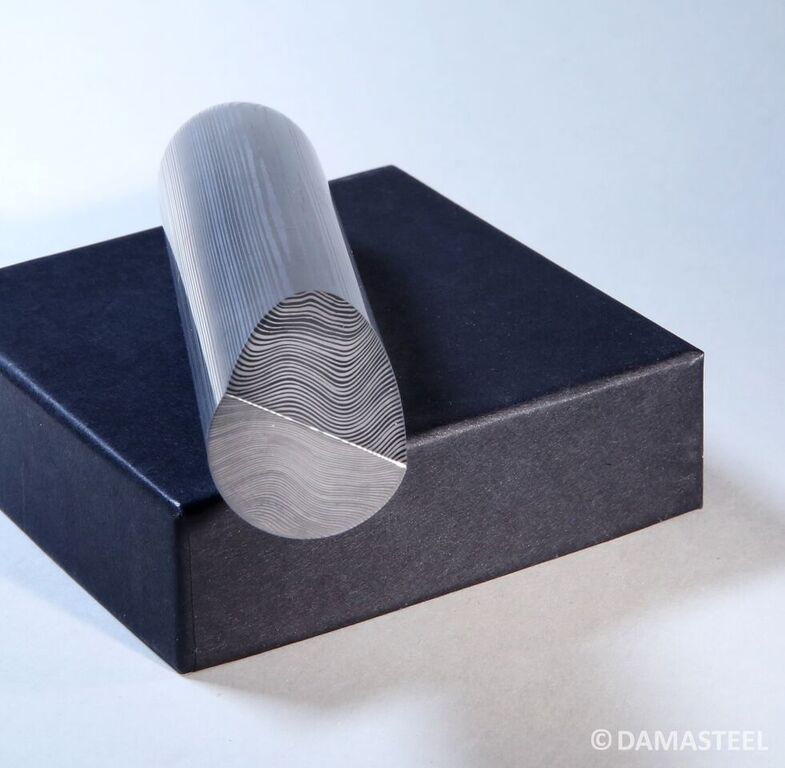

The majority of my work is done with Damasteel rapidly solidified powdered steels. RWL34 which is a martensitic stainless steel and does not have any pattern and the Damascus that they make from RWL34 and PMC27. Also see www.damasteel.com

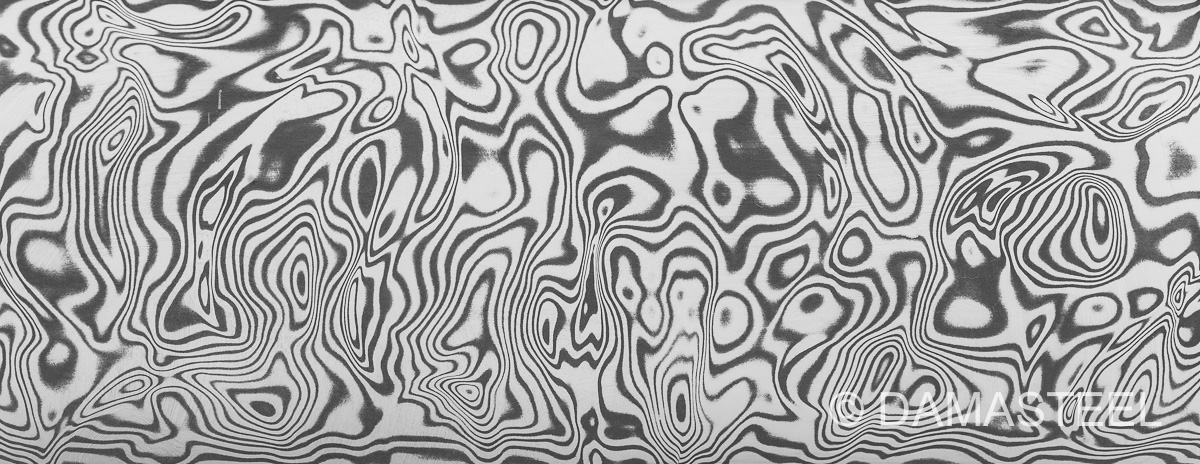

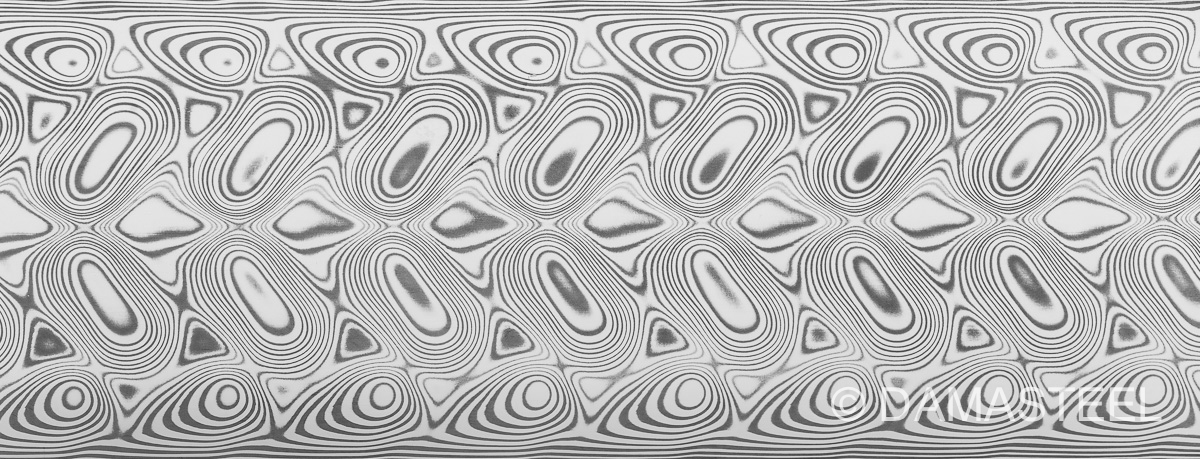

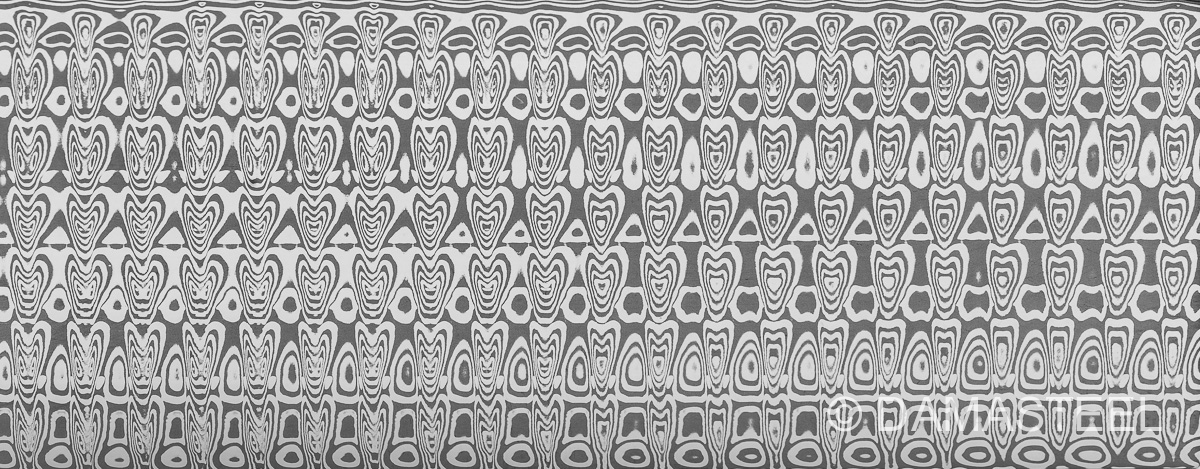

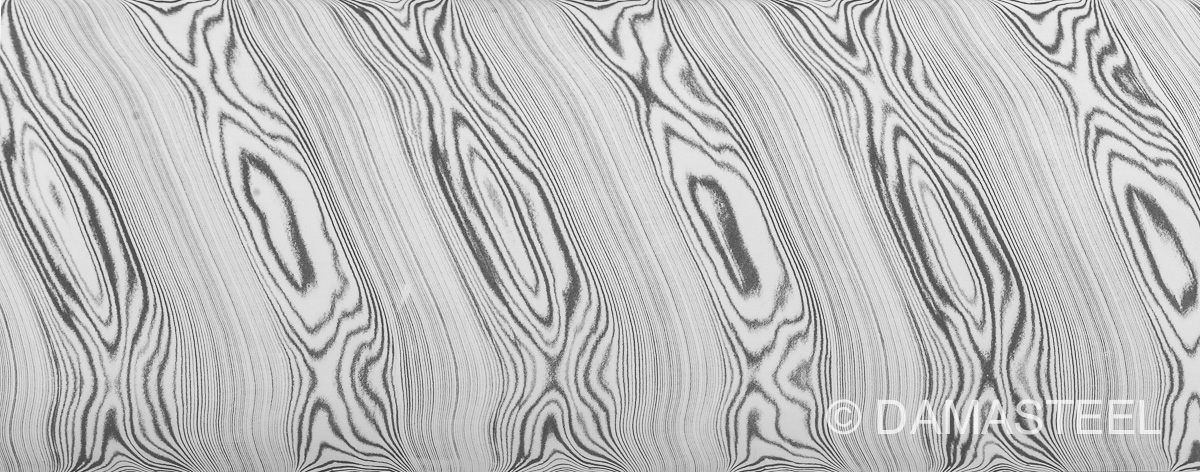

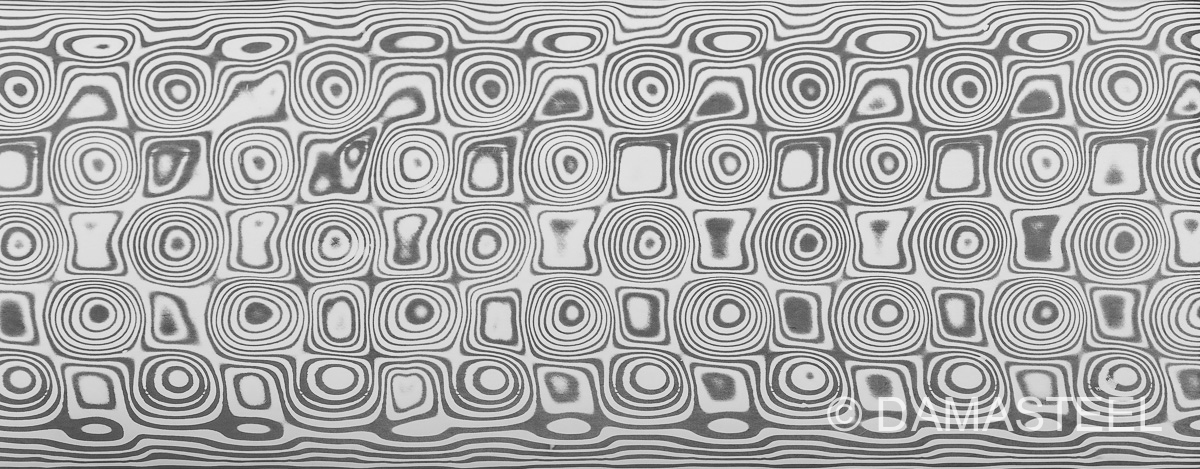

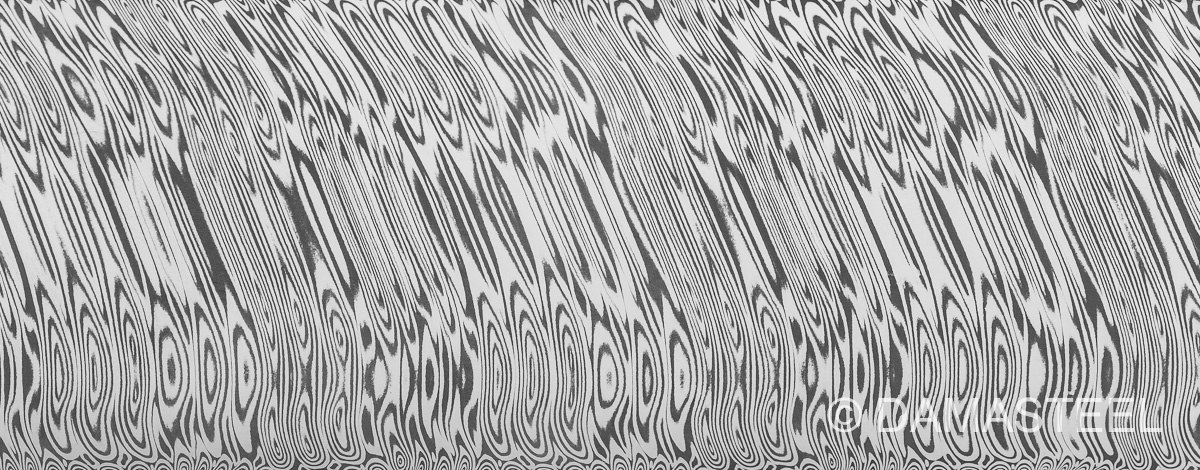

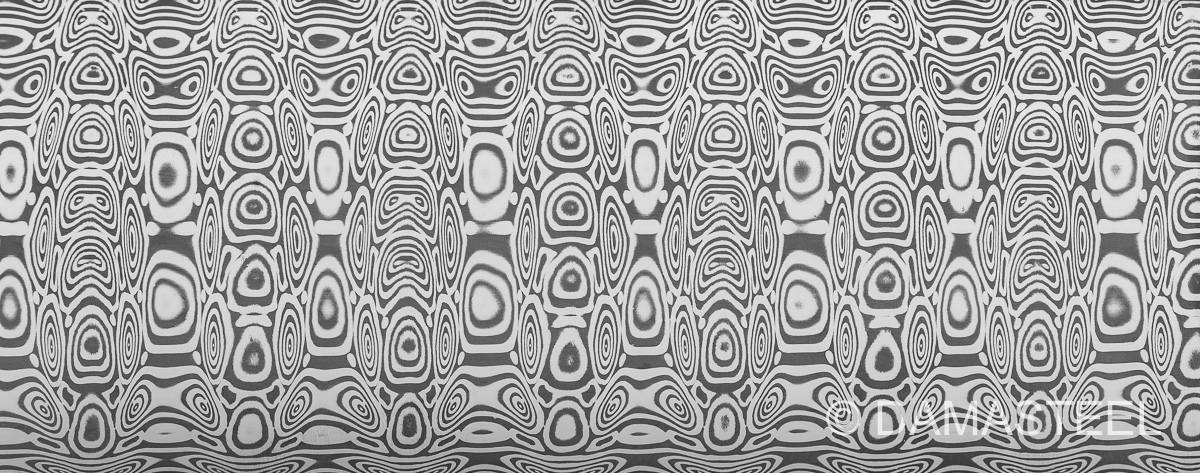

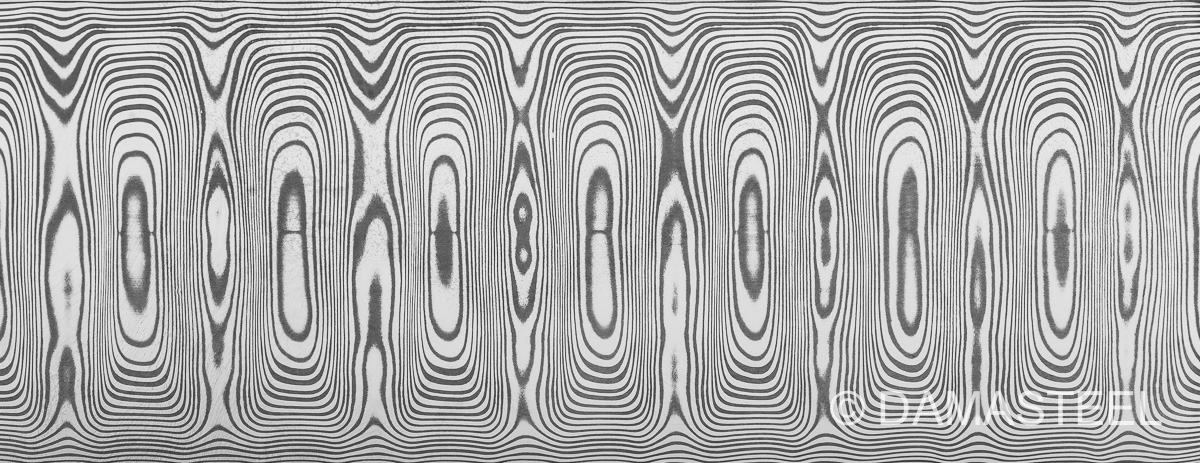

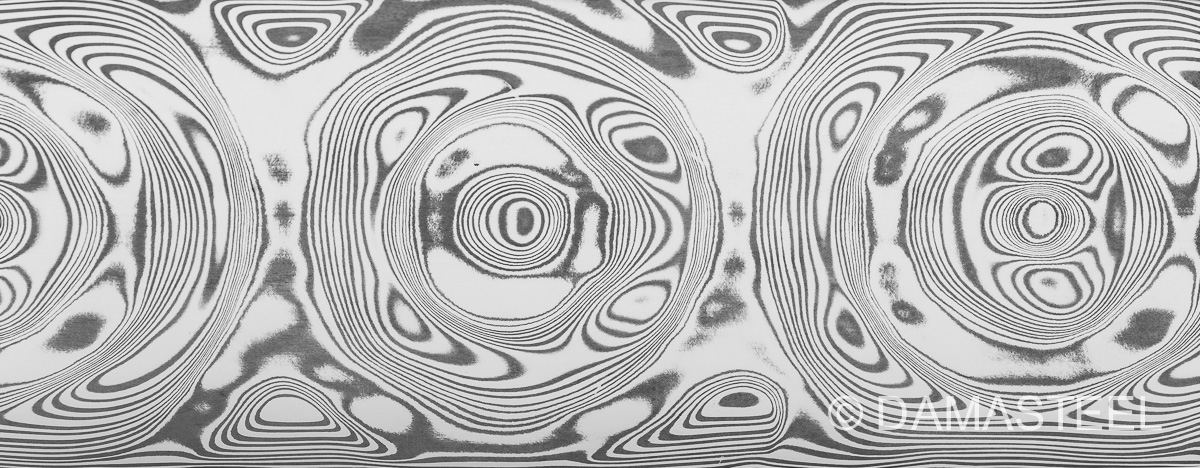

Damasteel have just announced the availability of the patterns below. If you are interested in any of these, please do get in touch via the Contact Me page

Data_Sheet_Martensitic_Damascus_Patterned_Steel

damasteel_broschure _2017_low copy

Data_Sheet_Austenitic_Damascus_Patterned_Steel

I have used other steels such as the Masami steel and Harley Damascus both made by Marcus Balbach.

Should you want something commissioned in a specific steel I have no problem in working with other steels however it is important that you supply me with the correct heat treating data so that when it comes to heat treating I get the absolute best performance from the steel. I do all my own heat treating in a digitally controlled kiln, this ensures that the heat treating process is absolutely accurate.

Non Ferrous Metals

I have added this section simply because I have been trying my hand at making Mokume. The process whereby thin sheets of copper, brass and or nickel silver are pressed together and heated to the point that they weld together. Gold and silver can also be used however this is something I will not be getting into soon?!

Once the “welded” block is out of the furnace it is then worked to give varying patterns resulting in some spectacular effects.

I have also made use of thin copper sheet as liners for handle material, the beauty of this is that the copper is workable (file work) on the edges and brilliant but subtle shapes can be left on the liner adding to the visual effect of that particular knife.

Woods

I try and use different woods which have well defined and extraordinary grain designs and patterns, not always possible but that does not mean that I stop looking!

As far as possible I will use stabilized woods due the fact they don’t move as much as natural woods. Having said that I have a large stock of the most beautiful Ebony that is more than 100 years old and was recovered from a church in the western Algarve.

Some spectacular wood that I have come across is Cork Oak and Olive. This region of the Algarve is known for its cork and Olive production.

Mammoth Ivory, Bone and horn

Exotic Materials